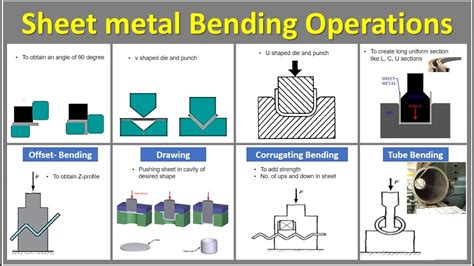

sheet metal roll bending This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . What is an Electricity Saving Box? An Electricity Saving Box, also known as an Energy Saver or Power Saver, is a compact electronic device designed to optimize the consumption of electricity in residential and commercial settings.

0 · types of sheet metal benders

1 · sheet metal bending standards

2 · sheet metal bending guidelines

3 · sheet metal bending guide pdf

4 · sheet metal bending design guide

5 · sheet metal bending basics

6 · problems with sheet metal bending

7 · maximum thickness sheet metal bending

HiI am Aman welcome to our youtube channel CAD PLUS CAM.About this video:-Friend in this video we will learn about how to use dry run mode in cnc machine.if .

This is where roll bending comes in. Roll bending is a highly effective technique for creating smooth, consistent curves in sheet metal and other materials. Using a series of rollers; you can achieve precise bends with minimal effort, reducing .

Roll bending, also known as plate rolling or angle bending, is a metalworking process that uses a series of rollers to bend a metal piece into a specific curve or radius. The metal is forced through the rollers, progressively .

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .The roll bending process uses 2, 3, or 4 rollers to shape the metal sheet into curves. The most common setup is the 3-roll configuration, where the rollers are set up in a triangle. The upper . Roll bending, also known as plate rolling or angle bending, is a metalworking process that uses a series of rollers to bend a metal piece into a specific curve or radius. The metal is forced through the rollers, progressively .Leading Manufacturer of Metal Forming Machines Innovative solutions for sheet metal forming machinery worldwide, delivering quality and precision. Nantong Shengli Heavy Machine in Numbers 2003 established 100+ products model .

types of sheet metal benders

The centre roll station of the sheet metal tools can be adjusted independently to create curved bends and the outer roll station retracted and locked to allow bending in curves. . Three-Station Sheet .

Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. Use the blade on the shear to make clean, straight cuts; it has two cutting edges for twice the life. A press brake makes bends up to 90°. Create curves and circles with the slip roll.. When using the shear or press brake, set the manual back gauge to .With a range of high quality metalworking sheet and plate metal bending rolls available we pride ourselves in being able to supply the best machine for you. For the best, highest quality metal working machinery and spares UK Wide call 01432 346 579

However, this design also has some drawbacks, such as low bending strength and a tendency for the sheet metal to fracture easily. The pressing process is a type of stamping process where a partially extruded material is used to force a groove onto the sheet metal, making it easier to bend and improving bending accuracy. A Finite Element (FE) 3D model of both the roll-bending machine and the metal sheet is used to simulate the mechanical behaviour of the metal sheet during the forming process, checking for the .

sheet metal bending standards

VEVOR Slip Roll Machine, 12.6 inches Forming Width in 20 Gauge Capacity, Sheet Metal Slip Roller Rolling Bending Machine, with 2 Detachable Rollers for Low Carbon Steel Copper Aluminum Alloy Sheet - Amazon.com. . this slip roll machine can roll sheet metal down to a minimum diameter of 1.25 inches, making it suitable for a wide range of fine .

3 roll and 4 roll Sheet metal and plate bending roll machines from American Machine Tools Corporation. PLATE ROLLS . Roll Benders . Interested in curving your sheet metal or plate? We have 3 roll and 4 roll benders that work by pinching the metal between the top and bottom rolls and curving it as it comes in contact with a back forming roll. . Buy VEVOR Sheet Metal Brake, 12-inch, 3-In-1 Combination Shear Brake Roll Machine, 20-Gauge Capacity Shear Press Brake with 90° Max Bending Angle, Shears and Slip Roll Machine for Shear Bending Rolling: Press Brakes - Amazon.com FREE DELIVERY possible on eligible purchases VEVOR Sheet Metal Brake, 12-inch, 3-In-1 Combination Shear Brake Roll Machine, 20-Gauge Capacity Shear Press Brake with 90° Max Bending Angle, Shears and Slip Roll Machine for Shear Bending Rolling 3.9 out of 5 stars 14 Mophorn 24 in. Slip Roll Roller Metal Plate Bending Round Machine, Slip Roll Machine Up to 16 Gauge Steel, Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers - Amazon.com . and cylinders from sheet metal. Our slip roll machine not only reels but can also cone the materials. The form bender is a useful tool for press .

sheet metal bending guidelines

Every bend in the metal sheet contributes to the functionality and appearance of the finished product, so precision in bending sheet metal is key to fabrication. Types of Metal Bending Roll Bending. Roll bending is a metal-bending technique that uses three rollers, a hydraulic press, and a brake to bend metal with precision. Types of Sheet Metal Rolling Machines. Sheet metal rolling machines come in various types to suit different applications. 1. Three-Roller Bending Rolls: These machines employ three rolls to bend metal sheets, offering precise control and versatility. 2. Four-Roller Bending Rolls: Incorporating an additional support roll, these machines provide .

sheet metal bending process involves the application of external force using a punch and dies at the specified length of the workpiece. Blog For Engineers and Hobbyist. . Minimum recommended bend radius For roll bending steel sheet . With the rapid development of the manufacturing industry, offshore oil and gas, petrochemical, coal chemical, heavy high-pressure vessel products are becoming more and more popular, thousand-ton hydrogenation reactor, .

- Sheet Metal Pedestal Band Ring Steel Roller Roll Metal Bending Machine - Overall Dimension: 24 in L x 11 in W x 43 in H *Rough Estimation* - Shipping Weight: 84 Pounds *Rough Estimation* - Pedestal Band Roller - Roller Is Designed For Hot-Rolled Or Mild Steel - The Pedestal Band Roller Will Roll Circles Rolls 8" Diameter And Larger - Heavy duty steel .

It can be used for steel tube bending, sheet metal bending, pipe bending, etc. Que: What factors influence bend angle and radii in metal bending? Ans : The bend angle and radius in metal bending are influenced by factors such as the material’s thickness, ductility, and hardness, the type of bending technique used, the radius of the bending .It is possible to bend sheet metal into rolls or curved forms with the use of the roll bending technique. Making small, medium and large round bends is possible with the use of a hydraulic press, an air brake and three sets of rollers. Using the spacing between rollers helps produce cones, tubes and hollow structures like cylinders and pipes. .We offer three types of Metal Slip Rollers for the fabrication industry. Our metal slip rollers are designed to form sheet metal into cylindrical shapes and bends. They are simple to operate and made of high grade alloy steel and hardened 50 HRC. Another metal slip roller is for our heavy duty Power Bending Rolls, equipped with robust 3.5" rollers designed for customers that bend .The Roll Bending (RB) process, also referred to as “plate rolling”, as opposed to the JCO and UO press-bending processes, is performed with a pipe rolling machine. This consists of a set of three or four rollers, positioned in a “pyramid” configuration to bend the plate into a pipe (Fig. 2.16).The plate passes several times through the rollers, which can move and gradually increase the .

VEVOR 12.6 in. Slip Roll Roller Metal Plate Bending Round Machine, Slip Roll Machine Up to 22 Gauge Steel, Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers - Amazon.com . and cylinders from sheet metal. Our slip roll machine not only reels but can also cone the materials. The form bender is a useful tool for press . Mophorn 12.6 in. Slip Roll Roller Metal Plate Bending Round Machine, Slip Roll Machine Up to 22 Gauge Steel, Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers - Amazon.com . and cylinders from sheet metal. Our slip roll machine not only reels but can also cone the materials. The form bender is a useful tool for press .Choose from our selection of sheet metal rolls, including metal, shim stock, and more. In stock and ready to ship. BROWSE CATALOG. . Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. . Make different edge styles on your sheet metal with these forming tools.Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. Use the blade on the shear to make clean, straight cuts; it has two cutting edges for twice the life. A press brake makes bends up to 90°. Create curves and circles with the slip roll.. When using the shear or press brake, set the manual back gauge to .

sheet metal bending guide pdf

7. Roll Bending Sheet Metal. With the roll bending method, bending metal sheets into rolls, curved shapes, cones, and tubes is made easier. It makes use of roller sets that bend metal sheets into the ideal shape or curvature. This method is perfect if you want to create workpiece parts that are not very thick. Some pros to consider: It is not .Sheet Metal Roll Bending Machines from Acrotech. Light to Medium gauge metal bending made easy. Horizontal and vertical roll bending machines for sale. Our 2 roll bending machines help streamline your large-volume needs for complete or partial cylinders with little or no flats on the ends. The roll bending machine models are designed to produce .

sheet metal bending design guide

sheet metal bending basics

A Septic Tank Distribution Box, also known as a D-box, is a junction box positioned between the septic tank and the drain field (or leach field). Its primary function is to evenly distribute the effluent (wastewater) from the septic tank into the various distribution lines within the drain field.

sheet metal roll bending|types of sheet metal benders